- Product description

- Features

- Installation method

Description

Self-supporting tubs installed on a visible framework consisting of flat rails.

The grids are perpendicular to the facades according to the layout plans.

The trays are made of 5 to 8/10th-thick sheet steel, perforated or not, with a wide choice of colors.

The trays, with sharp, abutting edges, are folded up at each end to ensure rigidity.

They rest on flat rails or self-supporting edge angles.

Usage

Open-plan office, meeting room, computer room

The materials

Galvanized steel, 0.5 to 0.8 mm thick depending on

widths.

Formats

Standard widths 300 / 600 / 675 mm

Other widths on request.

Lengths within self-supporting limits

(675 x 1800 mm maximum)

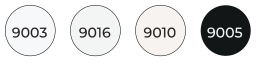

Colors

– Pre-painted white 137 (similar to RAL 9003)

– Post-lacquered polyester powder paint RAL :

– All other RAL colors on request

Light reflection

Report CSTB EMI 18-26077242-1 :

Up to 88% post-lacquered RAL 9016

Summary in the Finishes section of the catalog

The fire

Reaction to fire (according to EN 13501-1)

Euroclass A1 for products :

– Unperforated pre-painted sheets

– Pre-painted sheets with non-woven fleece or rock wool filling

surfaced

Euroclass A2-s1,d0 for products :

– Post-painted trays with or without lining

Acoustics

Acoustic certificates on request

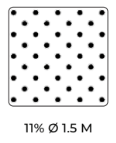

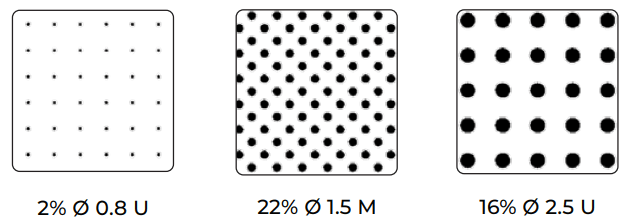

Perforations

Standard :

On request :

Options

Special cut-outs for lighting fixtures and HVAC equipment.

Activation of bins in hot/cold mode.

Heavy-duty bins (L)

Fire-resistant (SF)

Long BJR edge for overlap between bins.

Cleaning

Metal ceilings are durable and easy to clean.

For dust: Dry cleaning with a soft cloth or vacuum cleaner with soft bristle brush.

For stains: Clean with a damp cloth soaked in a non-abrasive cleaner diluted in water. For persistent, greasy stains, diluted alcoholic solutions can be used.

The environment

100% recyclable ceiling, odorless, easy to maintain and non-generating of dust, particles or vapor.

No VOC or formaldehyde emissions.

(Class A for rockwool-based trays).

EHDS sheet available on the INIES website (www.inies.fr).

All special profiles available on request

Installation in accordance with DTU 58.1

Frames: Trays laid on flat rails (various widths, with or without shadow gap) Hangers

positioned at 1200 mm centres, starting 300 mm from the wall. Clamping of

is imperative, using spacer profiles such as counter-drilled angles, to prevent any

to prevent any movement of the framing that could cause the panels to fall.

Edges: Panels are installed on single angle or hollow joint.

Dismantling: Open by pushing vertically.

1- EC2 BO tray

2- REC L edge angle

3- PREC LP flat rail

4- SUSP LP hanger

5- Connection splice RACC LP